Background

Workplace falls are some of the most common causes of injuries and fatalities in the workplace. According to the Occupational Safety and Health Administration (OSHA), falls account for about 15% of all accidental deaths and 25% of all nonfatal workplace injuries in the United States. The consequences of workplace falls can be devastating and expensive. Employees may suffer from physical pain, emotional trauma, disability or death, and this may have a chilling effect on the workplace environment.

Slips

Slips occur when there is little to no traction between the footwear and the walking surface. Since friction is not adequate to keep feet from slipping, a person can lose their balance. For example, a mechanic may slip on fluids from the car they are working on.

Trips

Trips happen when a person’s foot hits an object or missteps on an uneven surface. This can disrupt a person’s balance and make them lose their footing. For example, a detailer may trip on a hose lying on the ground.

Falls

Falls can happen to anyone when they stumble and fall too far off their center of balance. For example, an employee may fall from a ladder while replacing a light bulb. According to OSHA, falls can be classified into two types:

- Fall at the same level. It occurs on the same working surface.

- Fall to a lower level. It takes place below a person’s working surface, common when working at heights.

Note: OSHA requires that fall protection be provided at elevations of 4 feet in general industry workplaces. In California, fall protection is required at a height of 30 inches or more in general industry workplaces. Cal/OSHA regulations require that employers must provide fall protection systems for employees working at the heights previously stated.

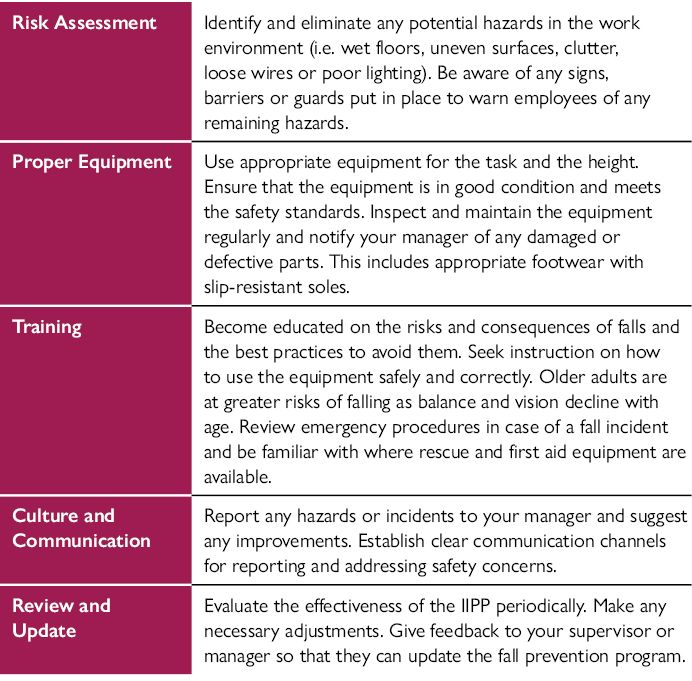

Prevention Strategies

It is essential to prevent workplace falls by following effective safety measures and practices. Here are some good practices to minimize the risk of slips, trips and falls in the workplace.

The best advice for avoiding workplace hazards is to always be aware of your surroundings.

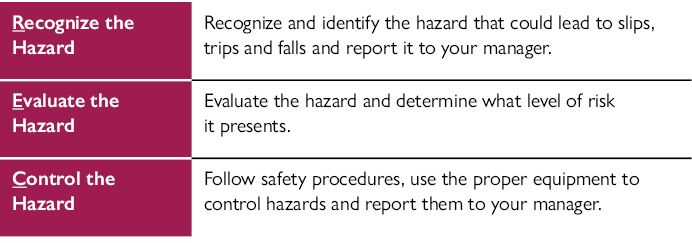

REC is a good three-step method to prevent slips, trips and falls in the workplace.

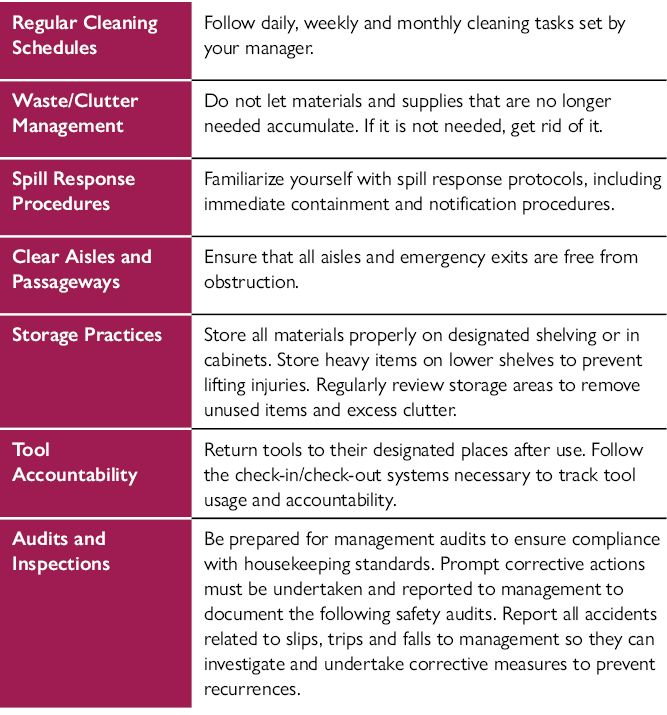

Good Housekeeping Practices

Call To Action

- Avoid Rushing: Do not hurry or take shortcuts — walk deliberately with sure footing to prevent trips and falls. No running or walking too fast. Avoid distractions; keep your eyes on the path ahead.

- Wear Nonskid Shoes: Use nonskid shoes that meet ASTM standards when working on wet, oily or greasy surfaces. Wear sensible shoes that provide good traction.

- Stay Alert: Keep your eyes on the path ahead and avoid carrying items that block your view. Unexpected hazards, such as an electrical cord left by the construction crew working in the area, may create a trip situation for the unwary.

- Clean Spills Promptly: Immediately clean spills and greasy spots with absorbent material. Icy patches should be covered with sand or other available slip-mitigating material. Use the mop bucket in the shop area to clean your area of all slippery material, such as lubricants or oily water.

- Warning Signs for Spills: Locate the Wet Floor signs and cones in your area. Use them to alert others of slippery conditions and contact your custodial services to clean spills promptly.

- Caution on Wet Surfaces: Walk slowly on wet floors with short, careful steps and toes slightly outward. Use fresh, clean mop water with a daily-added degreaser, and replace dirty water promptly.

- Ensure Adequate Lighting: Maintain proper lighting by replacing burnt-out bulbs and keeping walkways clear, especially in marginally lit areas. Keep aisleways and passageways clear.

- Use Ladders Safely: Check that ladders are in good condition, clean and free of oil or grease. Report and set aside any damaged ladders. Do not use boxes, milk crates, pallets and chairs as stools. Only use ANSI Type I or II rated step ladders and step stools in the work environment.

- Navigate Stairs Carefully: Step securely from one stair to the next; report any worn carpets or broken steps and avoid running or jumping on stairs. Keep stairways clear and hold handrails.

Conclusion

Following preventive measures significantly reduces slip, trip and fall risks. Using shop safety shoes that meet ASTM guidelines is integral to preventing slips, trips and falls. Regular training, inspections and collaboration between employers and employees are key components of an effective fall prevention program.