Cal/OSHA requires training for each employee, including managers, in heat illness prevention before starting any work that has the risk of exposure to heat. Managers, in their supervisory role, must be able to understand the causes, prevention, and symptoms of, and remedies for heat stress. They are responsible for ensuring each employee is offered and completes the employee heat illness prevention training, keeping training records, reviewing the draft Heat Illness Prevention Program (HIPP) provided on our Celly Services Inc. E-Learn site, and making site-specific changes as necessary. The HIPP must be available to all employees. Guidance for managers on Heat Illness Prevention is provided below. For complete details, please refer to your HIPP by clicking the link.

https://www.dir.ca.gov/title8/3395.html

Background

Both Cal/OSHA and Federal OSHA require that employers take affirmative and preventative actions to reduce heat stress. The law, enacted in California several years ago and updated in 2015, requires employers to train all employees — supervisory and non‑supervisory — to prevent heat stress. This memo provides you with guidance on the statute and steps you may take to comply with the law and protect employee health. Cal/OSHA requires you to show your HIPP and proof of employee training on heat stress when they inspect your facility.

Workers who are exposed to extreme heat or work in hot environments may be at risk of heat stress. Exposure to extreme heat can result in occupational illness and injuries. Heat stress can result in heat stroke, heat exhaustion, heat cramps or heat rashes. Heat can also increase the risk of injuries in workers as it may result in sweaty palms, fogged-up glasses and dizziness. Burns may also occur because of contact with hot surfaces. Such stress can affect employee judgment.

Current law applies to “outdoor places of employment.” Employees working outdoors, such as salespersons and porters in the lot, technicians and parts delivery drivers are at a high risk of heat stress. Shops with marginal ventilation, metal roofs and/or hot engines idling may increase the ambient temperatures, making heat stress an issue. All managers must be familiar with their Heat Illness Prevention Program in its entirety.

Monitoring Weather

Managers should check the extended weather forecast in advance using weather forecasting tools such as The OSHA-NIOSH Heat Safety Tool provided by the Centers for Disease Control’s National Institute for Occupational Safety and Health. A work schedule must be planned based on weather conditions. For example, heavy-duty jobs should be scheduled for early (cooler) parts of the day. To access the OSHA-NIOSH Heat Safety Tool, click the link.

https://www.cdc.gov/niosh/topics/heatstress/heatapp.html

Swamp Coolers

Portable evaporative coolers should be installed in the shop area during hot summer days. The size and number of coolers will be determined by the size and airflow in the shop area. The coolers are an electrical appliance and should be used with caution. The operating manual for the cooler must be reviewed by the shop staff. Test your coolers and A/C systems at your facility. It is better to address defective or compromised cooling systems now rather than wait for extreme weather. Fans in the shop area provide limited relief and as such swamp coolers may become necessary to cool workplaces. During periods of high humidity, fans may provide better relief than swamp coolers.

Start a Conversation With Your Employees

The conversation should be about the possible impact of hot ambient temperatures, working with hot machinery and the various means of alleviating the effects of heat. Training should include topics as follows:

- Closely Observe: All employees shall be closely observed by a supervisor or designee during a heat wave. For purposes of this section only, OSHA regulations state “heat wave” is any day in which the predicted high temperature for the day will be at least 80 degrees Fahrenheit and at least 10 degrees Fahrenheit higher than the average high daily temperature in the preceding five days.

- Acclimatize: An employee who has been newly assigned to a high heat area shall be closely observed by a supervisor or designee for the first 14 days of the employee’s employment.

- Drink Water: Remind employees to drink water and stay hydrated. You must provide accessible, cool drinking water.

- Assess and Use Body Cooling Gear: Managers should evaluate personal cooling gear such as neck gaiters and skull caps for employees. Cooling gear is available for $5 to $10 each. Training in proper usage of cooling gear is relatively easy. Current available gear specifications indicate that the gear can cool the body up to 30 degrees, activates in less than 60 seconds with just water and stays cool for up to two hours. The cooling cloth technology is chemical-free, machine washable and reusable. Body cooling gear must not be loose, such that it could get stuck in moving machinery.

- Pay Special Attention if You Have High Blood Pressure And/or Diabetes: Heat impacts people with diabetes and/or high blood pressure in a severe manner. Employees with those ailments should discuss with their MD regarding extra precautions to be taken in hot summer months and/or working in with hot equipment and machinery.

- Get the OSHA App for Your Cell Phone: Employees can download the “OSHA-NIOSH Heat Safety Tool” app to their phones and get the local Heat Index, Hourly Heat Index, Symptoms of Heat Stroke, First Aid for Heat Stroke and other safety tips. To download the app, click this link.

https://www.cdc.gov/niosh/topics/heatstress/heatapp.html - Use the Buddy System: Heat exhaustion can hinder an employee’s ability to rationally think and even create confusion. Each employee will be assigned a “buddy” to be on the lookout for signs and symptoms of heat illness and report to the supervisor immediately. Also, ensure that emergency procedures are initiated when someone displays possible signs or symptoms of heat illness as listed in the paragraph on the next page titled “Response to Heat Illness.”

Note: Employee Heat Illness Prevention Training material has also been provided to management for review and circulation to all employees. Document all employee training.

Employee Training

Employee training must include:

- Environmental and personal risk factors for heat illness.

- Different types of heat illness and the common signs and symptoms of heat illness.

- Employer’s procedures for complying with OSHA HIP requirements.

- Importance of immediately reporting to the employer, directly or through the employee’s supervisor symptoms of heat illness in themselves, or in coworkers.

- Use of a buddy system for monitoring heat stress and preventing heat illness, including seeking timely medical attention.

- Importance of frequent consumption of small quantities of water.

- Importance of acclimatization.

- Access to a cool, shaded break room where employees can rest during their break or cooldown periods.

- Use of the OSHA-NIOSH Heat Safety Tool to understand and prevent heat illness.

- Employer’s procedures for emergency responses to symptoms of possible heat illness and how medical services will be provided should they become necessary.

- Procedures for contacting emergency medical services, and if necessary, for transporting employees to a point where they can be reached by an emergency medical service provider.

- How to provide clear and precise directions to the work site.

Be Prepared for Emergencies — Post Signs on Employee Notice Board

Post signs for your employees on the notice board providing the following information:

- Steps to follow if a work has signs or symptoms of heat‑related illness.

- Who to call for medical help and how to give clear directions to the worksite if calling 911.

- How to provide first aid until the ambulance arrives.

How to Implement Appropriate Acclimatization

- Employees should ease into work. Nearly 3 out of 4 fatalities from heat illness happen during the first week of work.

- Gradually increase time working in hot conditions over 7 to 14 days.

- A new employee’s schedule should be no more than 20% of the usual duration of work in the heat on Day 1 and no more than a 20% increase each day.

- For workers with recent experience, their schedules should be no more than 50% of the usual duration of work in heat on Day 1, 60% on Day 2, 80% on Day 3, and 100% on Day 4.

- Closely supervise new employees for the first 14 days or until fully acclimatized.

- Non-physically fit workers require more time to fully acclimatize.

- Acclimatization can be maintained for a few days of non‑heat exposure.

- Taking breaks in air conditioning will not affect acclimatization.

Rest and Cool Down

- Permit rest and water breaks when a worker feels heat discomfort.

- Modify work/rest periods to give the body a chance to get rid of excess heat.

- Assign new and unacclimatized workers lighter work and longer, more frequent rest periods.

- Shorten work periods and increase rest periods:

- As temperature and humidity increases.

- When there is no air movement.

- If protective clothing or equipment is worn (i.e. paint suit).

- For heavier work.

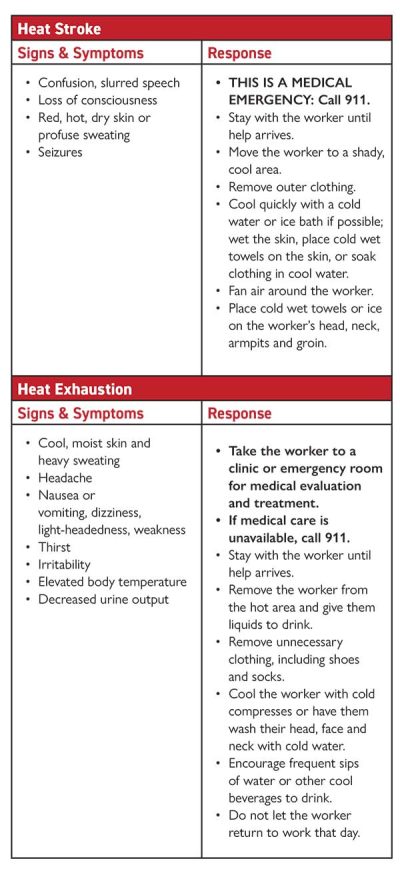

Response to Heat Illness

Management and all employees must understand the signs and symptoms of, and first aid and emergency responses to heat illness. OSHA provides this guidance for employers knowing that an MD is generally not available on site to diagnose, treat or respond to heat‑related illness. The following guidance is a quick tool from the OSHA‑NIOSH Heat Safety Tool app to use in the event of heat‑related illness. Guidance from an MD should be followed as required. The app also provides information on heat cramps and heat rashes.

Is Your Shop Indoors or Outdoors?

The HIP law applies to outdoor places of employment; OSHA’s interpretation of outdoor places may include your covered or enclosed shop areas. See the interpretation from OSHA below.

What Is Meant by “Outdoor Places of Employment?”

An outdoor place of employment is best thought of as one that is not an indoor workplace. A workplace with a roof and enclosed sides is generally considered an indoor workplace.

For the purposes of this standard, the distinguishing quality of indoor workplaces is that they reduce the risk factors that commonly lead to heat illness. For information about environmental risk factors for heat illness, click the link.

https://www.dir.ca.gov/dosh/heatIllnessQA.html

For example, a building that provides sufficient ventilation and cooling, either by natural or mechanical means, and blocks exposure to direct sunlight is considered an indoor workplace. Sheds, packing sheds and partial or temporary structures such as tents, lean-tos and structures with one or more open sides can be either indoor or outdoor workplaces, depending on the circumstances. In many cases, these structures may be hotter than the environment outside because of heating by the sun and conditions inside like limited air circulation or lack of insulation. A structure in this category may be considered an outdoor workplace if it does not significantly reduce the net effect of the environmental risk factors that exist immediately outside of the structure.

DISCLAIMER: The contents of this newsletter are for informational purposes only and are not to be considered as legal advice. Employers must consult their lawyer for legal matters and EPA/OSHA consultants for matters related to Environmental, Health & Safety. The article was authored by Sam Celly of Celly Services Inc. who has been helping automobile dealers in Arizona, California, Hawaii, Idaho, Nevada, New Mexico, New York, Texas and Virginia comply with EPA and OSHA regulations for over 35 years. Sam is a Certified Safety Professional (No. 16515) certified by the National Board of Certified Safety Professionals. Sam received his BE (1984) and MS (1986) in Chemical Engineering, followed by a J.D. from Southwestern University School of Law (1997). Sam is a member of the American Chemical Society (No. 31176063), American Industrial Hygiene Association (No. 124715), and National Association of Dealer Counsel (NADC). Sam also serves on the Board of Orange County American Industrial Hygiene Association and on the CA Industrial Hygiene Council (CIHC). Our newsletters can be accessed at www.epaoshablog.com. Your comments/questions are always welcome. Please send them to sam@cellyservices.com.